Tips for tension

Editor’s note: Today’s post about tension comes from our friends Susan Rubino and Chris Wenz over at Over the Top Quilting Studio in Austin, Texas. The two are longtime Austin-area APQS representatives and longarm quilters. Thanks for the article, guys!

In quilting there is only one word that is equal to a four letter word except it has 7 letters … TENSION! Yes, tension is the one problem that all quilters will encounter at some time in their quilting career. However, with careful and methodical adjustments you can have perfect balance.

When you begin the process of quilting you want to be sure that the machine is clean and free of dust or lint, which can wreak havoc and exacerbate your tension issues. Even a tiny piece of lint can intermittently upset your balance.

Remove your bobbin brake spring from inside the case and clean underneath it. Replace it so that the “fingers” on the brake spring face out of your bobbin case. They put pressure on the bobbin and stop it from overspinning when you change directions. Remember – one insidiously hard place to find lint is under the tension spring in your bobbin case. Be sure to use a business card to get under there, never a pin!

The number one way to be sure that you have your bobbin tension set correctly is to use the “drop test.” This is a surefire method to determine if your tension is set just right. Here’s what you do: Hold the bobbin case with a filled bobbin in one hand and hold the thread tail in the other. Lower your hand with the bobbin case and allow the bobbin to free float. It should fall about 4 inches if you give the thread tail a slight jerk. This is a good place to start, but you can adjust the drop more or less depending on your thread type and bobbin type.

If the bobbin case releases too quickly you will want to tighten the screw ever so slightly. We use our thumb fingernail but you can also use a tiny flat-blade screwdriver. If you find when you give the bobbin a quick jerk and it doesn’t move at all, you need to loosen the screw. When we get that bobbin set properly, we tend to just leave it as it is, never coming back to it if there are further tension issues.

So now that you have your bobbin set it is time to check the top tensioner. On the APQS family of machines there is only one tension disk and thank goodness for that! The ease of only checking one place for tension truly helps alleviate your personal tension level. Be sure that your thread is going through the thread path correctly. Tension problems oftentimes are misdiagnosed when in fact it is an improper thread path!

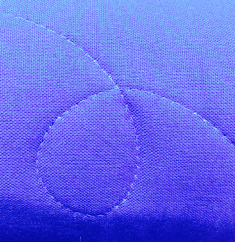

Tension that is too loose

The photo above shows the back of a quilt and is an example of top thread tension which is too loose. You can see that the top white thread is creating “railroad tracks” on the backside of the quilt. An easy way to tell if there are railroad tracks on the bottom side of the quilt is to run your fingernail along the bottom stitching and you will be able to both feel and hear your nails rapping against the threads. The top thread needs to be drawn up into the quilt sandwich to make a pretty stitch on both sides.

One other way to handle tension issues is to avoid them. We tend to use pre-wound bobbins almost exclusively. That way we know that when we insert a new bobbin, no adjustments need be made in the bobbin area.

Of course, changes in the weight of the top thread will likely require some tweaking. To do that, you need to be at ease with making modifications to your top tensioner. We recommend to our clients that they think of the tensioner knob as if it were the face of a clock. If changes need to be made, we tell them to assertively turn the knob a full 30 “minutes” either to the right or the left in order to make an appreciable change in the tension pressure. Remember, righty-tighty, left-loosy! The best way to keep track of your changes is to make a small mark on the tension knob as a reference point.

TENSION! A perfect word to describe one of the headaches of quilting. With these tips you now have a few ways to no longer let it get the better of you. You too can achieve perfect balance in your quilting life!

Susan Rubino and Chris Wenz own Over the Top Quilting Studio in Austin, Texas. The two are longtime Austin-area APQS representatives and longarm quilters. Thanks for the article, guys!