Tips for using specialty threads

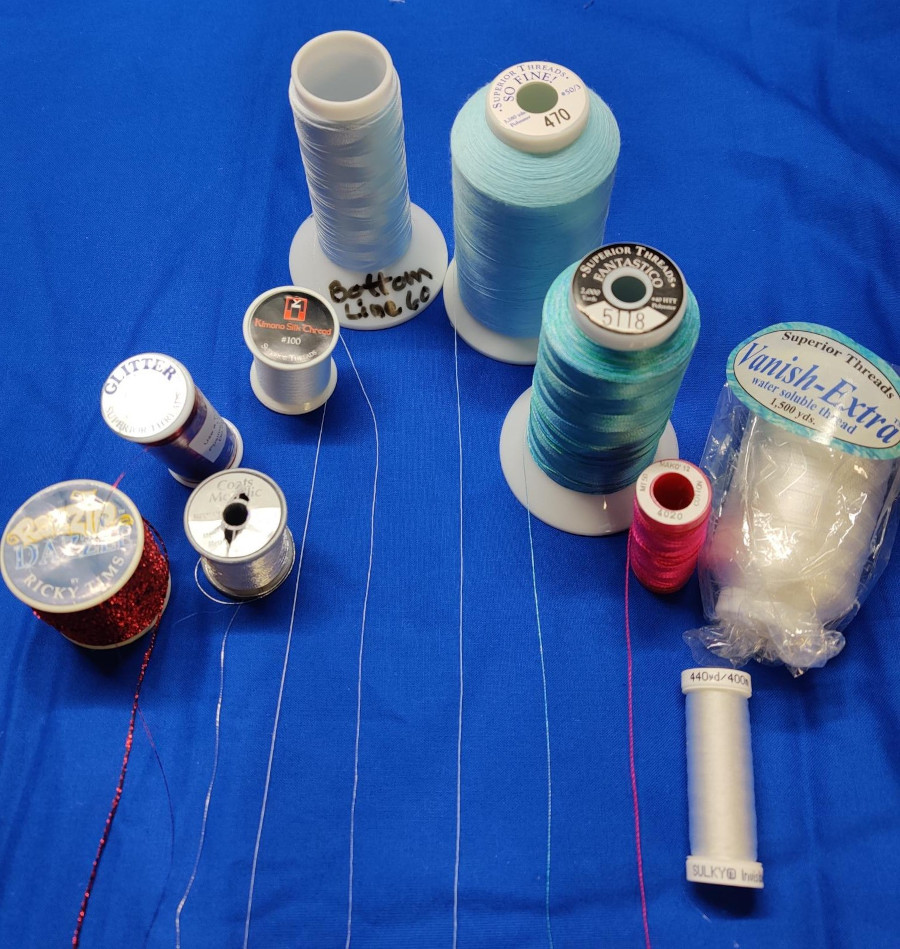

I don’t know about you, but I am a kid in a candy store when it comes to thread! There are so many beautiful threads – thin, thick, polyester, cotton, metallic, invisible – I love them all!

The good news is that it’s very easy to adjust the tension on APQS machines, which lets you use the wonderful array of thread choices available.

Running specialty threads successfully

Specialty threads can offer great versatility to your quilting, but they can also be tricky. It is important to remember considering both the weight of the thread and the type of thread material when making adjustments (keep reading for more information).

Impacts of a thread’s weight and thickness on needle size

The weight of a thread has to do with how thick or thin the thread is. The most common thread to use for longarm quilting is a 40- or 50-weight thread and a 4.0 needle.

Here are a few guidelines based on the weight and thickness of your thread to consider:

- Use a thinner thread (60 or 100 weight) if you want the thread to make less of an impact, or your design has a lot of backtracking (like feathers), and you don’t want a lot of thread build-up. You may need to loosen your tension and change to a smaller needle (3.5). Reminder: to loosen your tension, turn counterclockwise.

- Use a thicker thread to make a statement, such as 28 or even 12 weights. Depending on your previous quilting project you may need to loosen or tighten your tension to accomodate and change to a larger needle (4.5).

- Remember that numbers for needles and thread go in the opposite direction. For needles, it’s a measure of the size of the needle hole. For thread, it’s a measurement of how many threads fit into a space. So, the smaller the number, the smaller the needle but the thicker the thread. The larger the number, the bigger the needle but the thinner the thread.

- Your APQS machine can handle needle sizes between 3.5 and 4.5 without needing to be retimed. Make sure you get 1955 MR needles available from the APQS store.

A word of caution about slippery threads…

Most specialty threads are slippery and more fragile than regular polyester or cotton. To accommodate this, try changing the thread path through the 3-hole guide by the tensioner to a weaving path instead of wrapping the thread around the guide. This can help reduce friction. If necessary, you can also skip the center hole on the guide.

Slippery threads also tend to slip down and pool at the bottom of the cone. To prevent this from happening you can use a thread net and/or roll up a 1” x 3” piece of cotton batting into a tube and place it in the large thread guide directly above the cone. The thread should be between the batting and the guide, not in the batting.

Keep in mind is that a slippery thread may need more stitches to secure it for starts and stops.

And finally, if a slippery thread doesn’t rotate the thread break sensor wheel correctly, try wrapping it around the wheel twice.

Types of thread material

Polyester

Most polyester threads tend to be very strong. Adjust tension according to the weight of the thread.

Trilobal polyester

This thread can be fragile and slippery. These threads are very shiny and may shred more easily. You may need to loosen both your top and bobbin tension and reduce your quilting speed. The thread may also have static build-up and stick to the side of the machine head, especially in winter. To prevent this from happening you can run a humidifier or rub the thread with a dryer sheet.

Cotton

Cotton thread tends to be fuzzy and grabby. Make sure you clean lint from your hook assembly often. You may need to loosen your tension. Consider using a thin polyester thread in the bobbin.

Silk

Silk is very fine (thin) and strong thread. You may need to loosen your tension.

Metallic

Metallic threads tend to be very fragile and slippery but look so luscious! Look for smoother threads vs rough textured ones for less breakage. Loosen your tension and reduce your quilting speed. If you go fast, you can actually melt the metallic thread and it breaks. Try using a 60-weight thread in your bobbin.

Invisible/Monofilament

Invisible thread comes in either polyester or nylon and can be slippery. I prefer polyester as nylon sometimes gets yellow and get brittle with age. Invisible thread is great when you have a lot of different colors and don’t want the thread to show, such as t-shirt quilts or applique. However, the tension needs to be very loose.

In the picture below you can see how the thread is too tight and corkscrews when pulled through the needle. The thread in the front of the photo has a gentle wave – this is okay. The cone is wearing a thread net. If used in the bobbin, don’t fill it more than halfway so you don’t end up overstretching the thread.

Invisible thread can wear grooves in your pigtail thread guides, so check them if you use this thread a lot and replace the guides as needed.

Wash-away thread

Use wash-away thread to stitch trapunto designs that secure the trapunto batting before trimming the excess batting away. After layering your quilt and stitching the trapunto design again with the top thread, rinse to remove the wash away thread. You may need to loosen the tension and slow down. Don’t use this thread for swimwear!

A tip to consider

Consider using thread that is cross-wound (usually on a cone). If you want to use stacked-wound thread (usually on a spool), consider using the Hartley horizontal spool holder from the APQS store.

Tension

As you can see from the list above, loosening tension for specialty threads is often necessary.

I try to run my bobbin and top thread as loose as possible and still get a good stitch. I find a TOWA gauge (available at the APQS store – choose L or M depending on the type of bobbin you have) very helpful when adjusting my bobbin tension. I use 60-weight polyester thread (Superior Thread’s Bottom Line) almost exclusively in my bobbin.

If you run different weights of bobbin thread, you may want to get another bobbin case for each different weight so you don’t need to adjust when you switch threads, just use the other bobbin case (again, select L or M).

Treat yourself to some specialty threads and try them out on your next project – they can really spice it up!